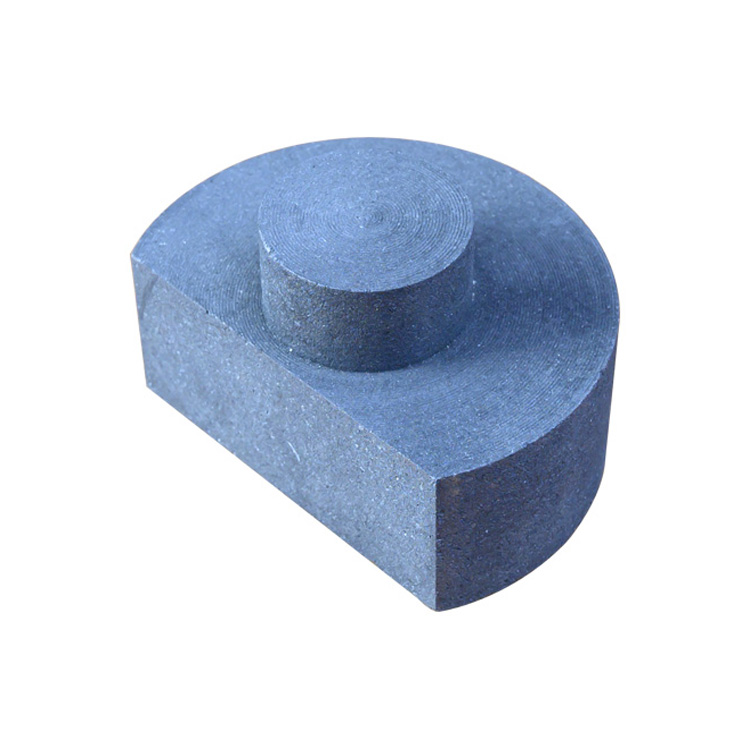

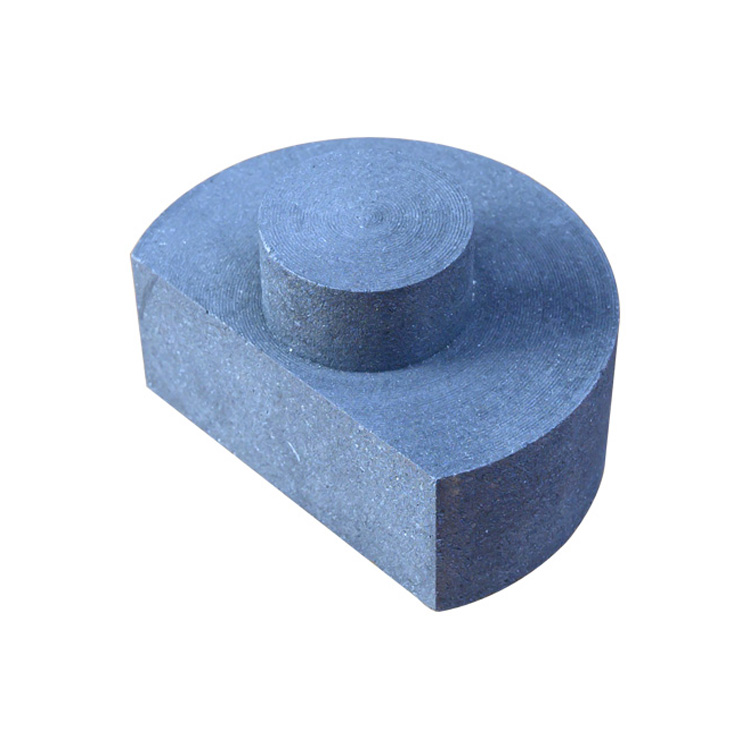

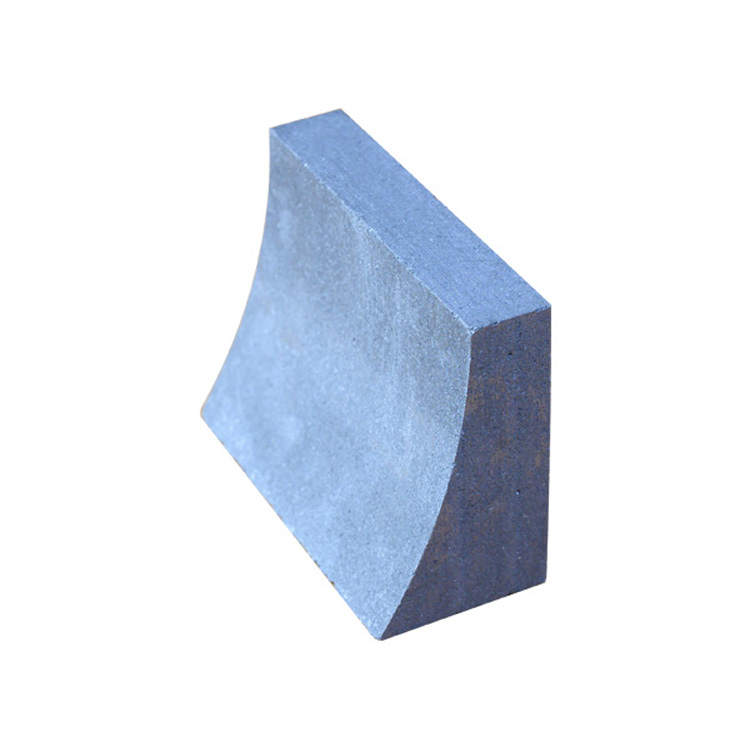

石墨冷铁

产品描述

在铸造时,常使用灰铸铁等金属作为激冷材料,由于灰铸铁等金属的导热系数小(2.0—2.5千卡/米.小时.度),常造成铸件的外部已经凝固了,内部还呈液体状态。等一段时间后虽然内部冷却凝固下来,但由于内部在冷却凝固时体积的缩小 ,常造成表面凹陷和内部质地疏松的缺陷。

一、石墨冷铁的优点:

1、能使铸件内外部尽快的同时冷却。由于石墨冷铁的导热系数大,短时间内吸热就多。使铸件内外部尽快的同时冷却,不但解决了铸件热节部位的质地疏松、缩孔问题,还使铸件金相组织为细片状珠光体达95%以上,共晶团数可达450—550cm,铸件硬度可提高20—50HB,提高了铸件表面的光洁度和耐磨性。

2、石墨冷铁易操作。由于石墨冷铁的比重小,约为金属冷铁的1/5左右,搬运时轻便,砂型(芯)翻箱时不易掉落。

3、石墨冷铁可重复使用,成本低。由于石墨冷铁的耐火度高达2800摄氏度,能耐高温,不易氧化的性能。不但避免了铸件产生白口(渗碳体)和气孔等铸造缺陷。其冷铁材料的表面还不易烫坏、氧化、龟裂,使用寿命比铸铁等金属材料冷铁长5—10倍。

二、石墨冷铁材料的使用方法:

在铸件需要激冷的热节部位安放成形的石墨冷铁造型(芯),其厚度为铸件热节部位园直径的0.6--1倍。如果用于铸铁件应在冷铁上涂刷石墨涂料,铸铜件可在冷铁上涂刷石墨涂料或滑石粉涂料,以防铸件增碳并随型(芯)烘干,效果更佳。我司特殊加工制成的石墨冷铁材料固定碳 >99% ;具有比重轻(比重 1.6-1.9克/立方厘米);耐火度高(耐火度 2800度);导热系数大(21千卡/米.小时.度)等优点。因此用我厂生产的石墨冷铁作激冷材料代替金属材料冷铁,能较好地解决铸钢、铸铁、铸铜、铸铝等铸件的疏松、缩孔问题。并能有效地解决铸件因使用金属冷铁产生的白口、气孔等铸造缺陷。

三、石墨冷铁注意事项:

1、请勿用尖锐物体用力敲打

2、禁止雨淋溅水

应用领域:铸钢、铸铁、铸铜、铸铝等冶炼行业

产品规格:根据客户尺寸、使用环境的要求定制生产

包装方式:木箱或者木笼+托盘包装

交货期:5-10个工作日,具体根据订单数量而定

Graphite chilling

Product description

In casting, gray cast iron and other metals are often used as chilling materials. Because the thermal conductivity of gray cast iron and other metals is small (2.0-2.5 kcal / m · h · d), the outside of the casting has been solidified and the inside is still in liquid state. After a period of time, although the interior is cooled and solidified, due to the shrinkage of the interior during cooling and solidification, the defects of surface depression and internal loose texture are often caused.

1.Advantages of graphite chill:

1. 1The internal and external parts of the casting can be cooled at the same time as soon as possible. Because of the high thermal conductivity of graphite chill, it absorbs more heat in a short time. By cooling the internal and external parts of the casting as soon as possible, not only the problems of loose texture and shrinkage cavity in the hot spot of the casting are solved, but also the metallographic structure of the casting is fine flake pearlite, the number of eutectic clusters can reach 450-550cm, the hardness of the casting can be increased by 20-50hb, and the surface smoothness and wear resistance of the casting are improved.

1.2 Graphite chilling is easy to operate. Because the proportion of graphite chilling is small, about 1 / 5 of that of metal chilling, it is light to handle, and it is not easy to drop when the sand mold (core) is turned over.

1.3Graphite chilling can be reused with low cost. Because the fire resistance of graphite chill is as high as 2800 ℃, it can withstand high temperature and is not easy to oxidize. It not only avoids casting defects such as white hole (cementite) and air hole. The surface of its graphite chilling material is not easy to burn, oxidize and crack, and its service life is 5-10 times longer than that of cast iron and other metal materials.

2.How to use graphite chilling material:

The graphite chill mould (core) is placed at the hot spot of the casting, the thickness of which is 0.6-1 times of the circle diameter of the hot spot of the casting. If it is used for iron castings, graphite coating should be applied on the cold iron. For copper castings, graphite coating or talcum powder coating can be applied on the cold iron to prevent the casting from carburizing and drying with the mold (core). The graphite cold iron material made by our company has the advantages of fixed carbon > 99%, light specific gravity (specific gravity 1.6-1.9g / cm3), high fire resistance (fire resistance 2800 ℃) and high thermal conductivity (21kcal / m · h · d). Therefore, using graphite chill produced by our factory as chilling material instead of metal chill can solve the problems of porosity and shrinkage of cast steel, cast iron, cast copper and cast aluminum. It can effectively solve the casting defects such as white hole and air hole caused by using metal chill.

3. Precautions for graphite chilling:

3.1 Do not use sharp objects to knock hard

3.2 No splashing

Application fields: steel casting, cast iron, cast copper, cast aluminum and other smelting industries

Product specifications: according to customer size, the use of environmental requirements for customized production

Packing method: wooden box or wooden cage + pallet packing

Delivery time: 5-10 working days, depending on the order quantity

津公网安备12011602300470号

津公网安备12011602300470号