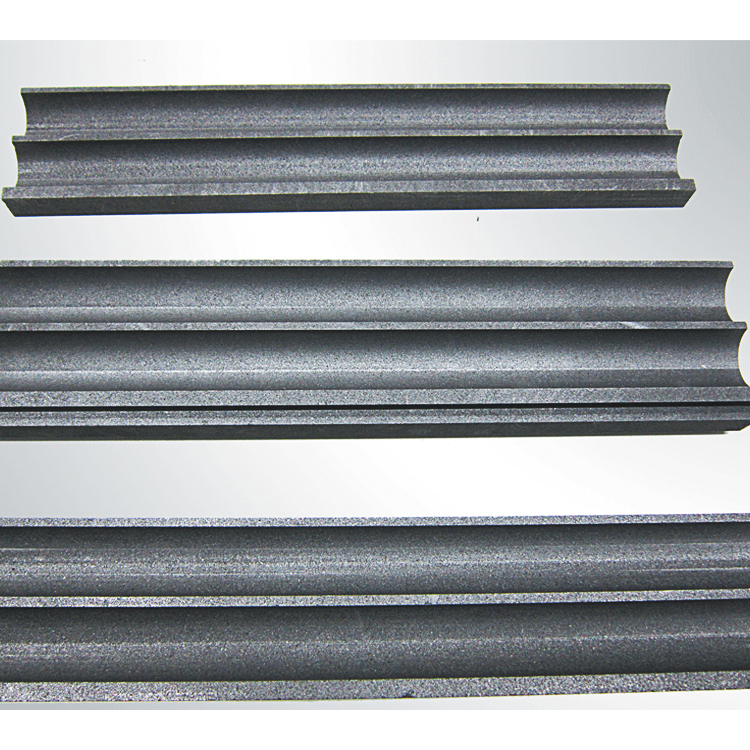

碳化硅耐磨抗氧化涂层

耐磨抗氧化涂层是由高性能碳化硅用cvd的方式附着在石墨表面进行复合得到的高性能耐磨抗氧化材料。广泛用于因冲蚀、气蚀和高温所需要的高性能材料,也用于在有耐磨、防腐要求的机件表面制备耐磨防腐涂层。

● 主要特点:

1.高温抗氧化:抗氧化,温度高达1600℃时抗氧化性能仍然非常好;

2.纯度高:高温氯化条件下化学气相沉积方法制得的;

3.耐冲刷:硬度高、表面致密、颗粒细;

4.抗腐蚀性:耐酸、碱、盐及有机试剂;

5.SIC表面层为β-碳化硅,属面心立方。

●产品应用:

太阳能光伏(温区加热、保护配件),航空航天(喷火嘴),半导体(外延生长用的石墨基座),化工(耐冲刷,耐腐蚀),核电等行业

Wear resistant and oxidation resistant SIC coating

The wear-resistant and oxidation-resistant SIC coating is a kind of high-performance wear-resistant and oxidation-resistant material, which is composed of high-performance silicon carbide and graphite surface by CVD. It is widely used in high performance materials for erosion, cavitation and high temperature. It is also used to prepare wear-resistant and anti-corrosion coating on the surface of machine parts with wear-resistant and anti-corrosion requirements.

Main features:

1. High temperature oxidation resistance: oxidation resistance, when the temperature is up to 1600 ℃, the oxidation resistance is still very good;

2. High purity: prepared by chemical vapor deposition under high temperature chlorination condition;

3. Erosion resistance: high hardness, dense surface and fine particles;

4. Corrosion resistance: resistant to acid, alkali, salt and organic reagent;

5. SiC surface layer is β - SiC, which belongs to face centered cubic.

津公网安备12011602300470号

津公网安备12011602300470号