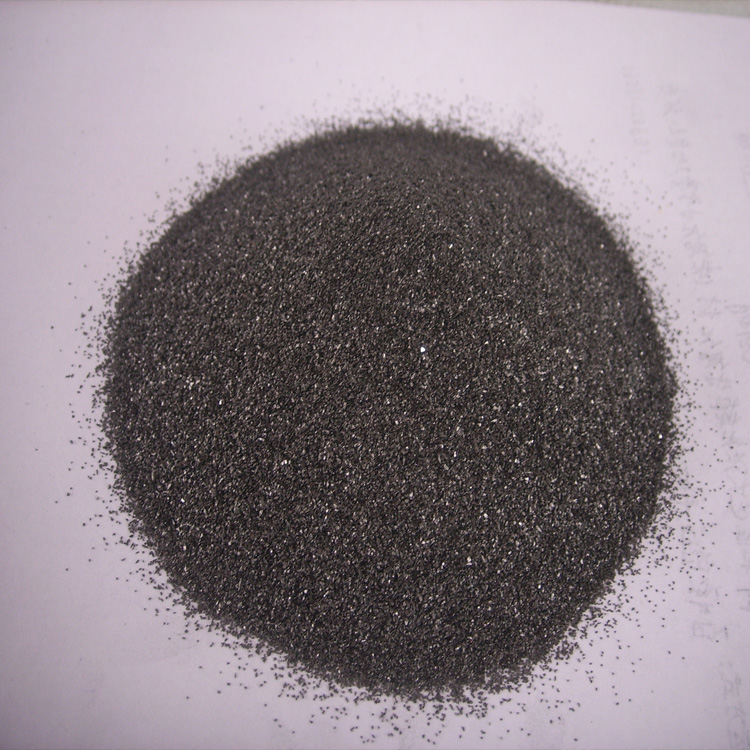

刹车片用增碳剂

产品描述

该产品微观结构有序,颗粒度区间设计科学,在机动车刹车过程中,能够*程度上保持刹车片的摩擦系数稳定,不会因为刹车导致刹车片脆裂,引起刹车失效,从而提高了刹车片使用过程中的安全性能。

2003年公司研发新工艺,克服了原材料供应不足的特点,达到月供货量4500吨,由于货量足,供货稳定,成为许多贸易公司及钢铁厂的*定供应商。

国内客户规模:钢铁厂用户11家,铸造厂68家,刹车厂47家。

具体*标如下

|

型号代码 |

固定碳 |

硫份 |

灰分 |

挥发份 |

水分 |

含氮量 |

|

DT-CA-01 |

97.00% |

0.50% |

1.50% |

1.50% |

0.50% |

N/A |

|

DT-CA-05 |

98.50% |

0.30% |

0.80% |

0.80% |

0.50% |

0.40% |

|

DT-CA-08 |

97.00% |

0.05% |

1.50% |

1.50% |

0.50% |

0.03% |

|

DT-CA-10 |

95.00% |

0.30% |

3.50% |

1.50% |

0.50% |

N/A |

刹车片用增碳剂

适宜的规格*标如下:DT-CA-01,DT-CA-05,DT-CA-08

推荐粒度:

1.40-120目(US MESH)90%

2. 30-150目(US MESH)90%

3.20-100目(US MESH)90%

|

型号 |

毫米 |

百分比(*) |

|

20 |

0.841 |

-0.002 |

|

40 |

0.420 |

-47.20% |

|

60 |

0.250 |

-42.50% |

|

80 |

0.177 |

-9.50% |

|

100 |

0.149 |

-0.5 |

|

PAN |

|

-0.30% |

以上颗粒度是持久推荐标准粒度,如您有特殊要求请联系持久技术部。

GPC for brake pads

Product description

The product has an orderly microstructure and a scientific grain size range design, and can keep the friction coefficient of the brake pad stable to the greatest extent during the braking process of the motor vehicle, and will not cause the brake pad Brittle crack and cause the brake failure, thereby, the safety performance of the brake pad in the use process is improved.

In 2003, the company developed a new process to overcome the shortage of raw material supply, reaching a monthly supply of 4500 tons, as a result of sufficient volume, supply stability, as many trading companies and steel plant designated suppliers.

DOMESTIC CUSTOMER SCALE: 11 Steel Plant users, 68 foundries, 47 brake plants.

FOREIGN CUSTOMER SCALE: Foreign Sales performance is good, customers in Japan, South Korea, India, the United States, Thailand, Vietnam, Malaysia, Russia, Ukraine, France and 22 other countries, and the use of manufacturers continue to increase, applications are not only expanding.

Specific indicators are as follows

|

Model Code |

Fixed Carbon (minimum) |

Sulphur (highest) |

Ash Content (highest) |

Volatile matter (maximum) |

Moisture (maximum) |

Nitrogen content (maximum) |

|

DT-CA-01 |

97.00% |

0.50% |

1.50% |

1.50% |

0.50% |

N/A |

|

DT-CA-05 |

98.50% |

0.30% |

0.80% |

0.80% |

0.50% |

0.40% |

|

DT-CA-08 |

97.00% |

0.05% |

1.50% |

1.50% |

0.50% |

0.03% |

|

DT-CA-10 |

95.00% |

0.30% |

3.50% |

1.50% |

0.50% |

N/A |

Carbon additive for brake pads

Suitable specifications are as follows: DT-CA-01, DT-CA-05, DT-CA-08

RECOMMENDED GRANULARITY:

1.40-120 Mesh (US Mesh)90%

2. 30-150 Mesh (US Mesh)90%

3.20-100 MESH (US MESH)90%

|

Model number |

MM |

Percentage (maximum) |

|

20 |

0.841 |

-0.002 |

|

40 |

0.420 |

-47.20% |

|

60 |

0.250 |

-42.50% |

|

80 |

0.177 |

-9.50% |

|

100 |

0.149 |

-0.5 |

|

PAN |

|

-0.30% |

The above granularity is the recommended standard granularity for persistence. If you have special requirement, please contact persistence technology department.

津公网安备12011602300470号

津公网安备12011602300470号