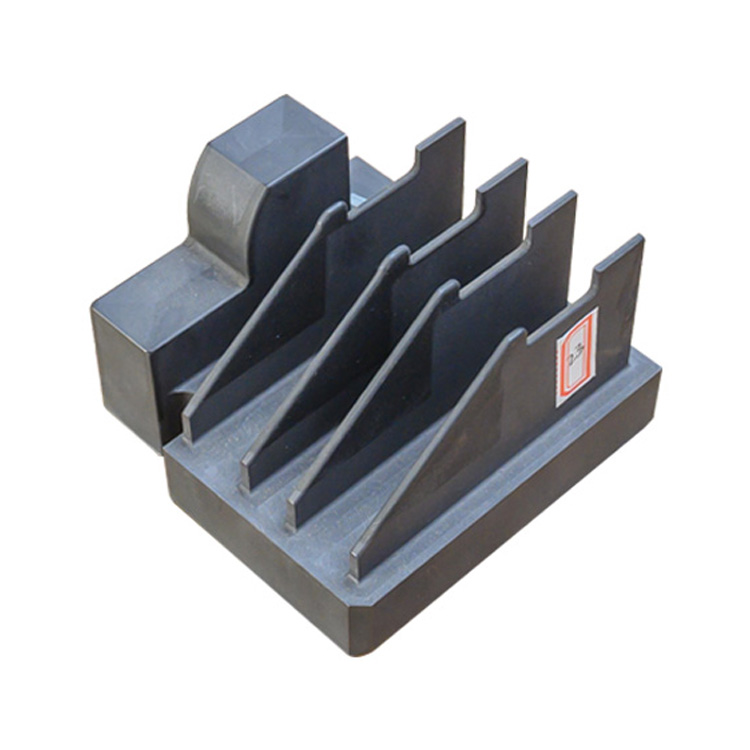

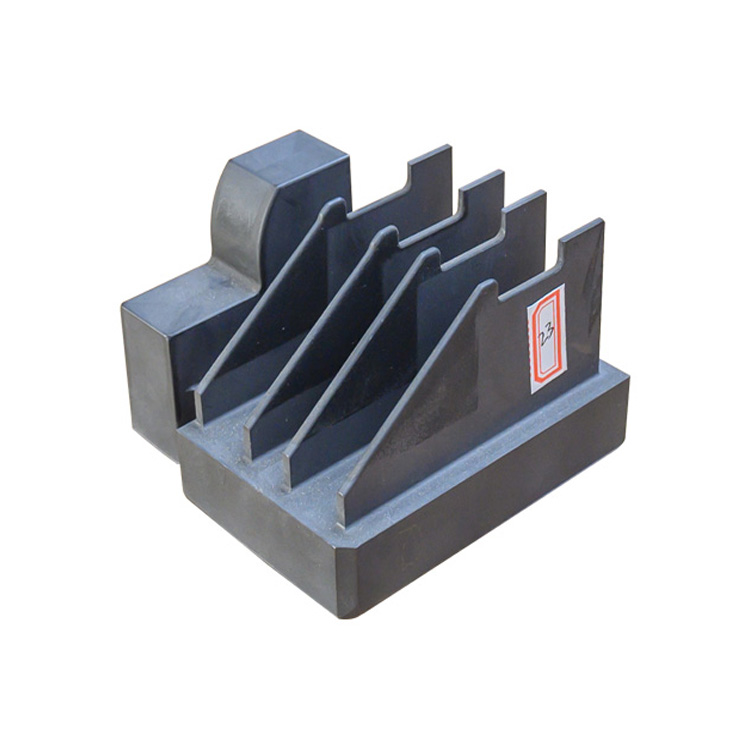

放电加工用石墨电极(EDM)

产品描述

作为模具加工领域广泛应用的一项工业技术,电火花加工始终发挥着重要的作用。在放电加工中为了保证模具的质量,电极的选用非常关键。在节能、*率成为制造业热点话题的形势下,电极的选用方面越来越多的客户开始选择石墨来取代传统铜来进行放电加工。事实证明石墨电极拥有铜电极不具有的*特性,提高了企业和产品的市场竞争力,提高了生产效率,带来了成本的降低和利润的增加。持久EDM电极模具有较高的切割速度和良好的性能表现。

主要特点:

1、重量轻(铜的五分之一),减低EDM的负载 ;

2、较高的放电加工速度(铜的1.5~3倍);

3、密度大、磨损率低 ;

4、热膨胀率低(是铜的热膨胀系数的四分之一),意味着受热变形的情况减少了,生产出来的产品*度更高;

5、大量不同的牌号可供选择,从粗加工、精加工到*终*加工

应用领域:广泛应用于电火花加工领域,

产品规格:根据客户尺寸、使用环境的要求定制生产

包装方式:木箱或者木笼+托盘包装

交货期:5-10个工作日,具体根据订单数量而定

Graphite electrical grade for EDM

Product description

As an industrial technology widely used in the field of mold processing, EDM has always played an important role. In order to ensure the quality of die in EDM, the selection of electrode is very important. Under the situation that energy saving and high efficiency have become hot topics in manufacturing industry, more and more customers choose graphite to replace traditional copper for EDM. It has been proved that graphite electrode has the high quality characteristics that copper electrode does not have, which improves the market competitiveness of enterprises and products, improves the production efficiency, reduces the cost and increases the profit. DURATIGHT EDM electrode mold has high cutting speed and good performance.

Main features:

1. Light weight (one fifth of copper), reduce the load of EDM;

2. Higher EDM speed (1.5 ~ 3 times of copper);

3. High density and low wear rate;

4. The low thermal expansion rate (one fourth of the coefficient of thermal expansion of copper) means that the thermal deformation is reduced and the accuracy of products is higher;

5. A large number of different grades are available, from rough machining, finishing to final precision machining

Application field: widely used in the field of EDM,

Product specifications: according to customer size, the use of environmental requirements for customized production

Packing method: wooden box or wooden cage + pallet packing

Delivery time: 5-10 working days, depending on the order quantity

津公网安备12011602300470号

津公网安备12011602300470号