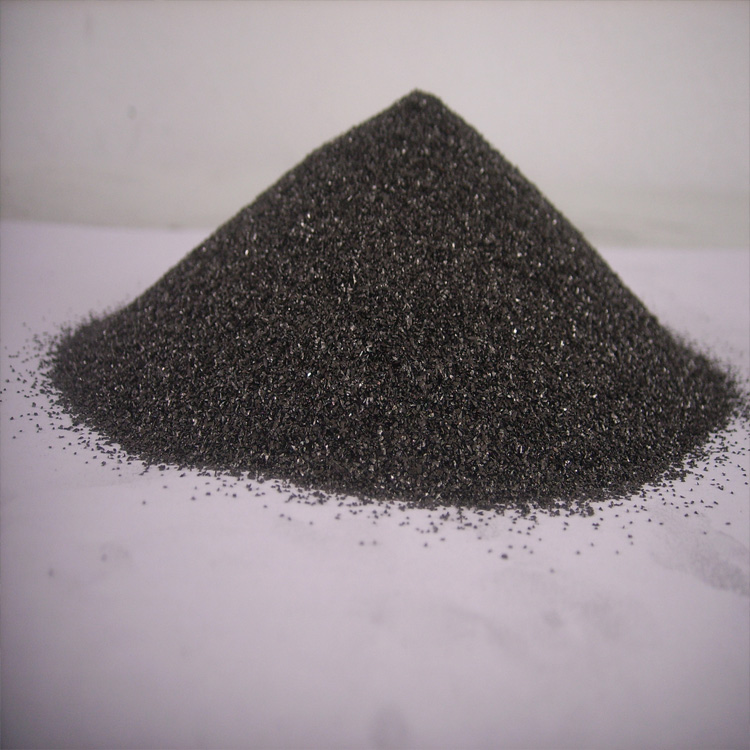

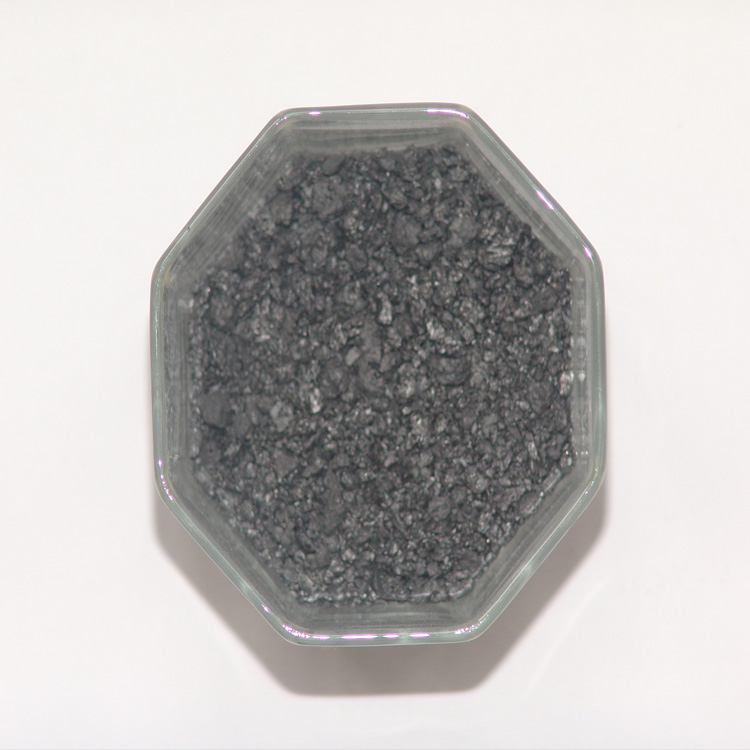

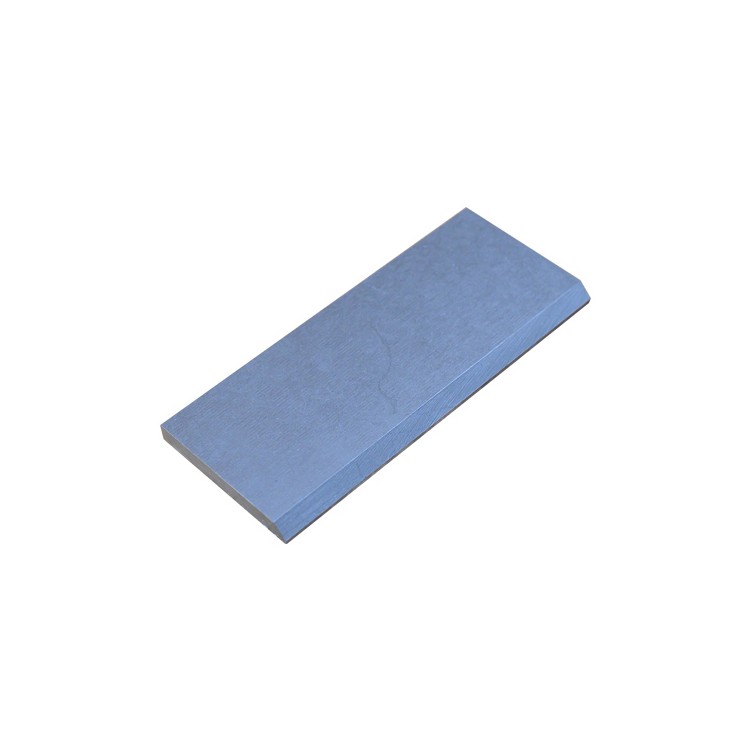

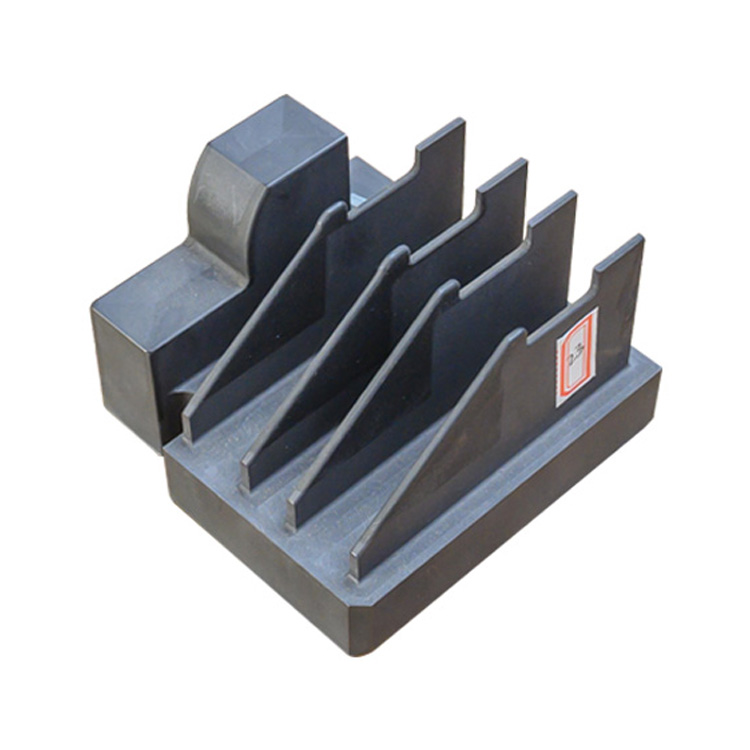

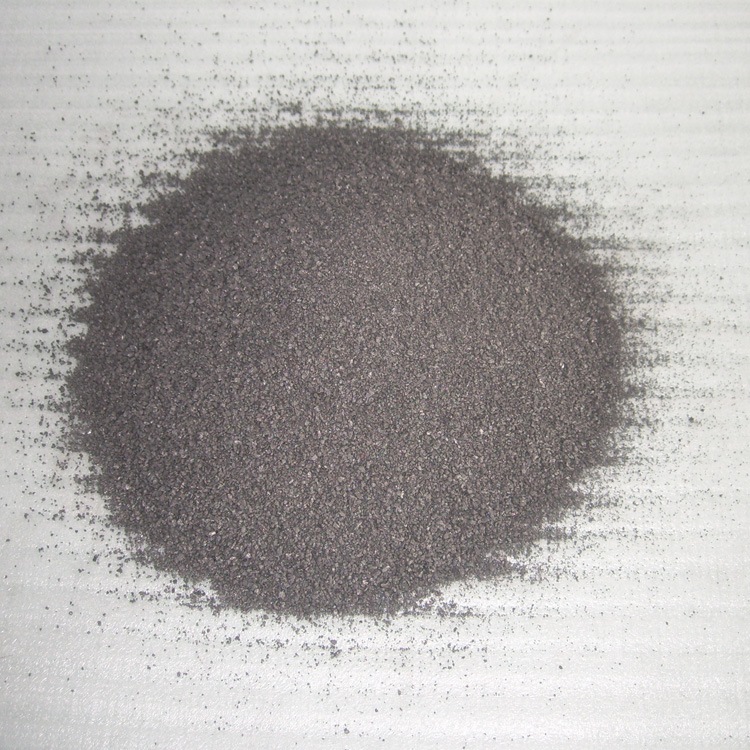

炼钢炼铁用增碳剂

产品描述

持久经过多年研发并结合客户应用经验生产的增碳剂,具有高碳、低硫、低氮、有害杂质少等优良特性,该产品是冶炼行业改进工艺、提高钢/铁液的一种新型材料,成为近年来各大冶炼厂冶炼生产时的增碳剂,持久增碳剂可促进铁液中石墨的形核能力,增加球墨铸铁的球墨数量,改善灰铸铁组织结构,并提高铸铁牌号。

2003年公司研发新工艺,克服了原材料供应不足的特点,达到月供货量4500吨,由于货量足,供货稳定,成为许多贸易公司及钢铁厂的*供应商。

国内客户规模:钢铁厂用户11家,铸造厂68家,刹车厂47家。

具体指标如下:

|

型号代码 |

固定碳 |

硫份 |

灰分 |

挥发份 |

水分 |

颗粒度 |

含氮量 |

|

DT-CA-02 |

98.50% |

0.50% |

0.80% |

0.80% |

0.50% |

1-5MM |

N/A |

|

DT-CA-06 |

99.00% |

0.30% |

0.50% |

0.50% |

0.50% |

1-5MM |

0.10% |

|

DT-CA-09 |

98.50% |

0.05% |

0.80% |

0.70% |

0.50% |

0.5-5MM |

0.03% |

|

DT-CA-08 |

97.00% |

0.07% |

1.50% |

1.50% |

0.50% |

0.2-1MM |

0.03% |

|

DT-CA-11 |

99.00% |

0.03% |

0.50% |

0.50% |

0.50% |

0.5-5MM |

0.03% |

|

DT-CA-12 |

80.00% |

0.10% |

16.50% |

3.50% |

2.00% |

1-5mm |

N/A |

使用持久所生产的增碳剂,生产铸件时可大幅度增加废钢用量,减少生铁用量或不用生铁。增碳剂特点是碳在铁液中吸收效果好,不返渣,使用增碳剂可大幅度降低铸件生产成本。

1、用途:用于特钢炼钢增碳和球铁铸造增碳。

2、产品特点:固定碳含量高,硫分低,增碳效果稳定,碳的吸收率高。

3、适用范围:用于各种电炉熔炼铸钢、铸铁的增碳。

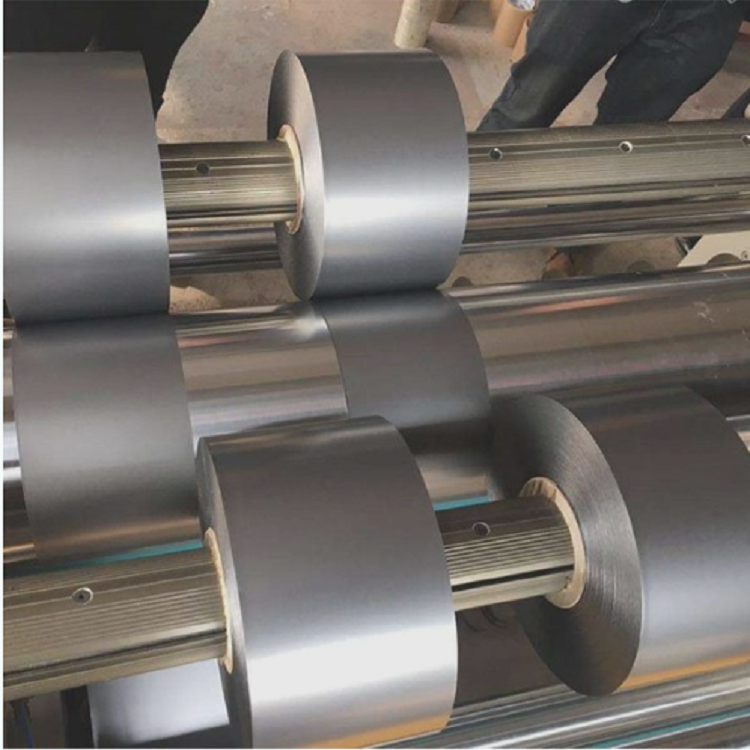

4、粒 度:常用粒度:0.3-3mm 1-4mm,1-3mm,3-5mm,3-8mm,5-10mm或按用户特殊要求供货。

5、使用方法:

1).使用5吨以上的电炉,原料单一稳定,我们推荐分散加入法。根据含碳量的要求按配料比,将增碳剂与金属炉料随各批料一同加入电炉中下部位。增碳剂在熔化时不要打渣,否则易裹在废渣里,影响碳的吸收。 2).使用3吨左右中频感应电炉,原料单一稳定,我们推荐集中加入法。在炉内先熔化或剩余少量铁水时,将需配加的增碳剂一次性加在铁水表面,并立即加金属炉料,将增碳剂全部压入铁水中,使增碳剂与铁水充分接触。 3).使用小型中频电炉,原料夹有生铁等高碳物质的,我们推荐增碳剂微调。钢/铁水熔化后,调整碳分,可以加在钢/铁水表面,通过电炉熔炼时钢/铁水的涡流搅拌或人工搅拌使本产品溶解吸收。

6.与传统生铁相比:

1) 本产品为非金属,熔点为1200-1300度左右,使用中无残留,利用率高。 2) 本产品便于生产使用,用量大大低于生铁,节省企业生产成本。 3) 本产品磷硫含量大大低于生铁,性能稳定。

专业的国内外配送运输经验及合作伙伴,专业的外贸操作人员,确保你的货物运输无忧。国内运输方式:汽运,铁路运输,海运;国外运输方式:铁路运输,海运,空运等,可以做FOB, CFR ,CIF ,DDU, DDP的运输条款项下的承运。丰富的装箱和包装经验,让您无需为运输担忧。

1. 防水吨袋包装,吨袋包装(不加小袋) 2.纸袋包装,20kg或25kg纸袋,外加吨袋或托盘 3.20kg,25kg袋,30kg防水编制(织)袋,外加吨袋或托盘

2.纸袋包装,20kg或25kg纸袋,外加吨袋或托盘

3.20kg,25kg袋,30kg防水编制(织)袋,外加吨袋或托盘

除以上包装方式外如您对包装有特殊要求,请您联系持久工程部。

Carbon Additive for casting

Product description

After years of research and development. Qingdao Duratight focus to supply customers carbon additive/Graphite Petroleum Coke(GPC) with high carbon, low sulfur, low nitrogen, less harmful impurities and other excellent characteristics, the product is a new type of material for improving the process and quality of Molten Iron and steel in smelting industry. It has become an optimum carbon additive in smelting production of major smelters in recent years. Duratight Brand GPC can promote the graphite nucleation ability in molten iron, increase the quantity of nodular graphite cast iron, improve the structure of gray iron, and raise the grade of cast iron.

In 2003, the company developed a new process to overcome the shortage of raw material supply, reaching a monthly supply of 4500 tons, as a result of sufficient volume, supply stability, as many trading companies and steel plant designated suppliers.

DOMESTIC CUSTOMER SCALE: 11 Steel Plant users, 68 foundries, 47 brake plants.

FOREIGN CUSTOMER SCALE: Foreign Sales performance is good, customers in Japan, South Korea, India, the United States, Thailand, Vietnam, Malaysia, Russia, Ukraine, France and 22 other countries, and the use of manufacturers continue to increase, applications continue to expand.

Specific indicators are as follows:

|

Model Code |

Fixed Carbon (minimum) |

Sulphur (highest) |

Ash Content (highest) |

Volatile matter (maximum) |

Moisture (maximum) |

Particle size (90%) |

Nitrogen content (maximum) |

|

DT-CA-02 |

98.50% |

0.50% |

0.80% |

0.80% |

0.50% |

1-5MM |

N/A |

|

DT-CA-06 |

99.00% |

0.30% |

0.50% |

0.50% |

0.50% |

1-5MM |

0.10% |

|

DT-CA-09 |

98.50% |

0.05% |

0.80% |

0.70% |

0.50% |

0.5-5MM |

0.03% |

|

DT-CA-08 |

97.00% |

0.07% |

1.50% |

1.50% |

0.50% |

0.2-1MM |

0.03% |

|

DT-CA-11 |

99.00% |

0.03% |

0.50% |

0.50% |

0.50% |

0.5-5MM |

0.03% |

|

DT-CA-12 |

80.00% |

0.10% |

16.50% |

3.50% |

2.00% |

1-5mm |

N/A |

By using the Duratight Brand Carbon Additive,the amount of scrap steel can be increased greatly, and the amount of pig iron can be reduced or no pig iron can be used. The carburant is characterized by good absorption of carbon in molten iron and no return of slag. The production cost of castings can be greatly reduced by using the carburant.

1. USAGE: used for special steel making and ductile iron casting.

2. Product features: High fixed carbon content, low sulfur content, stable carburizing effect, high carbon absorption rate.

3. SCOPE OF APPLICATION: It is used for carbonizing cast steel and cast iron in various electric furnaces.

4. GRANULARITY: Commonly used granularity: 0.2-1mm 1-5mm, 1-3mm, 3-5mm, 3-8mm, 5-10mm or according to the special requirements of users.

5. How to use:

1) . The use of more than 5 tons of electric furnace, a single stable raw material, we recommend the method of decentralized addition. According to the requirement of carbon content, the carbon additive and the metal charge are added into the middle and lower part of the electric furnace together with each batch. Carbon Additive in the melting do not slag, or easy to wrap in waste slag, affect carbon absorption. 2) . Using about 3 tons medium frequency induction furnace, the raw material is single and stable, we recommend the method of centralized adding. When a small amount of molten iron is melted or left in the furnace, the carbon additive should be added to the surface of the molten iron once, and the metal charge should be added immediately, and the carbon additive should be pressed into the molten iron to make the carburizing agent in full contact with the molten iron. 3) . Using small medium frequency electric furnace, raw material clip has pig iron and other high carbon material, we recommend carbon additive fine adjustment. After Molten steel/molten iron, the carbon content can be adjusted and added to the surface of the steel/molten iron. The product can be dissolved and absorbed by Eddy current or manual stirring of the steel/molten iron during melting in an electric furnace.

6. Compared with the traditional pig iron:

1) this product is non-metal, melting point is about 1200-1300 degrees, no residue in use, high utilization. 2) the product is easy to produce and use, the consumption is much lower than pig iron, and the production cost of the enterprise is saved. 3) the phosphorus and sulfur content of this product is much lower than pig iron, and its performance is stable.

Professional domestic and foreign distribution and transportation experience and partners, professional foreign trade operators, to ensure that your cargo transportation worry-free. DOMESTIC MODE OF TRANSPORT: Motor Transport, Railway Transport, sea transport; foreign mode of Transport: Railway Transport, sea transport, air transport, can do FOB, CFR, CIF, Ddu, Ddu, DDP under the terms of transport. Rich experience in packing and packaging, so that you do not need to worry about transportation.

1. Waterproof ton bag packing, ton bag packing (no small bag)

2. Paper bags, 20kg or 25kg paper bags, plus ton bags or pallets

3.20kg, 25kg bags, 30kg waterproof woven bags, plus ton bags or pallets

In addition to the above packing methods, if you have special requirements for packing, please contact the durable works department.

通过商机365

通过商机365

津公网安备12011602300470号

津公网安备12011602300470号